Production/ Development System

For more than 80 years from the start of operations in 1924, Mitsubishi Electric Nagoya Works has manufactured various universal devices including motors, programmable controllers and inverters. The history of AC servo production at Nagoya Works spans over 30 years. We have expanded our production system based on the technology and tradition amassed during this time, and have incorporated world-class research and development to create high-performance, high-quality products that can be supplied for a long time.

Production System

To guarantee the high quality and performance of MELSERVO, Mitsubishi Electric has built a cooperative system of three facilities – Shinshiro Factory, a branch factory of Nagoya Works; Mitsubishi Electric responds to various need throughout the world by uniting technologies and know-how of these facilities. Mitsubishi Electric’s FA energy solutions, “e&eco-Factory”, are at work in the servo motor factory at the Nagoya Works. They are being used to boost capacity utilization and product quality, and reduce energy consumption.

Development System

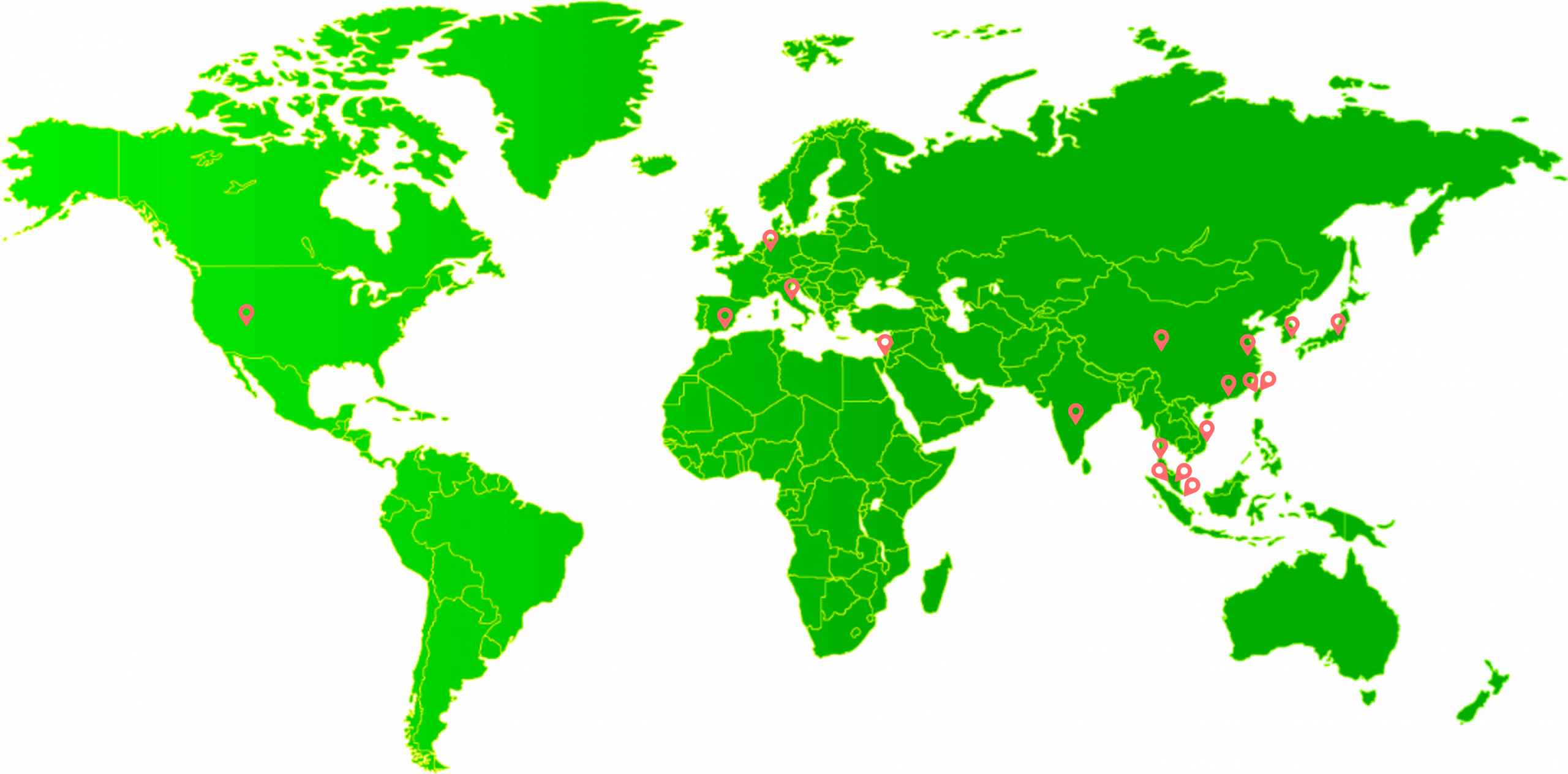

To spread advanced servo systems to the world as quickly as possible, Mitsubishi Electric has established FA-related development centers at its Nagoya Works, and in North America and Europe. Furthermore, we have established strong connections between our Advanced Technology R&D Center, which pushes technology development beyond the limits of FA, and Information Technology R&D Center. We are moving forward with the development of new products that reflect the latest technological directions and customer input.

SSCNET Partner Association (SNP)

The SSCNET Partner Association (SNP) carries activities to introduce the advanced servo system controller network “SSCNET” and compatible products to many users. In cooperation with partner corporations, SNP widely promotes the performance attainable with SSCNET. In recent years, SNP holds partner meetings in Japan and other countries such as Taiwan and India. SNP aims to make SSCNET a more global servo system controller network.